|  |  | ||

| ||||

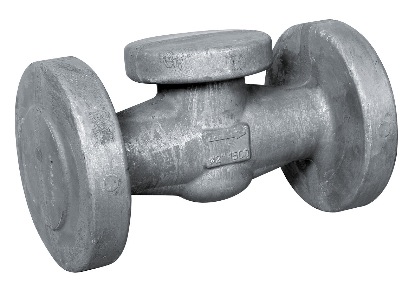

Feat is based to the north of Milan, in the area called Brianza, where the art of processing steel was practised in bygone times to make arms and equipment for the city which took on the services of the famous Leonardo da Vinci. Feat cherishes these traditions and, over a long and constant activity, its development of a multitude of products has led it to accumulate a level of experience which is unique in the world for its width and complexity. - Some examples in the petrochemical field: Body, Bonnets, Bonnetless, Cap, Adaptor, Union End, Flange, Nut, Plug, Papillons, Clamp, Diaphragm Valve, Disc, Gate, Segment, Exstension, Camseal, Butt Welding, Butterfly, Steam Traps, Wedge, Level’s Indicator, … - Some examples in the Hydraulic Cylinder field: Membranlock, Membranstod ,Cylinder, Piston Head, Eye and Dump End, End Cap, Trunnion, Trackrod Link, Polish Rod Clamp, Collar, Crew, Piston rod and Cylinder End and Lug, Yoke … - Some examples of earth-moving machines and mechanical engineering in general: Safety screw, Sleeve, link, Teeth, Side cutter, Trigger, Ratchet Housing, Tool Retainer, Cover, Scraper Tooth, Crawler Pad, Connector, Ring, Bielle, Support, Fit Lock, Drum Cap, Brake Anchor Plate, Brake Spider, Gear, Planetary, Link Panhard, Bracket, Axel Seat, Stub Shaft , Mounting Holes, King Pin … Feat’s technical office is always at your disposal to create brand-new solutions or work on new projects which our clients propose.

A broad range of mechanical pressing lines is ready to mould small items up to 100 kg. Counterblow hammers are used for parts with larger dimensions up to 500 kg. The technology applied is a point of reference for the entire industry, and the solutions developed are constantly evolving. Most of the production lines are automated using anthropomorph manipulators, and special efforts have been made to automate processes, so that the highest level of repeated quality is assured without compromising the flexibility which is our hallmark. All projects regarding installed plant have been developed by Feat staff and they are constantly reviewed in order to ensure continued improvement.

Our task is to provide ready-to-use mechanical components, so it is necessary to apply adequate machining operations, for finishing and testing, to unrefined parts. 3 vertically-organised divisions have been created to ensure the greatest levels of competence. The first concentrates on the creation of valve components, capable of processing high-alloy materials, producing addition of hard metal, to the point of designing and assembling terminated and customised valves. The second concentrates on the processing of components for high-pressure hydraulic cylinders and on large-size parts made of heat-treated steels which are required for the earth-moving sector. The third conducts the more refined ‘high-precision’ operations typically for parts transmitting movement. The machinery and solutions employed are maintained constantly in step with technological innovation and are set out in order to obtain the greatest levels of productivity or flexibility, depending on need.

The completion of suitable cycles of heat treatment guarantees mechanical characteristics (at high temperatures or at room temperature), toughness (at room temperature or at various temperatures below freezing), the microstructures, the resistance to oxidation and corrosion, which are required by the strictest international regulations (EURONORM, ASTM, ASME, RCCM), as well as by the technical specifications of our clients. Our philosophy is one of supplying finished components which are ready for assembly. Some of the final operations include: sand-blasting, progressive marking, painting, surface treatment, calibrating, assembly and all the other operations defined at the planning stage.

Forged elements are produced in the following materials: - carbon steel – low, medium and high alloy steels – stainless, austenitic and martensitic steels, duplex, precipitation hardening steels – creep resistant steels and steels for valves - nickel and super-alloys based on nickel – titanium alloys. All these materials come from the best European steelworks and are approved by Feat using its own selective standards. The greatest attention is paid to the cutting stage in order to avoid defects which could affect the finished product. At all times, chemical analysis can be made to avoid non-conforming mixes or composition.

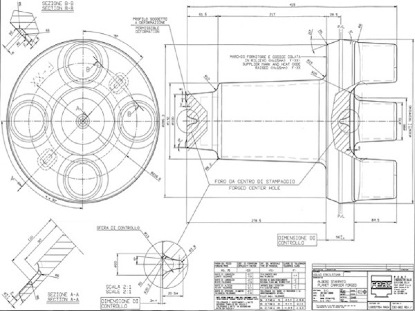

The heart of our business is revealed in the ability to engineer the best production processes and moulding equipment to achieve optimal mechanical components that meet the needs of our customers. Feat Group in its long history has developed specific expertise in the production of mechanical parts targeted at original equipment manufacturers, serving the strategic sectors of modern society (petrochemical, industrial lifting and earth moving equipment). Feat seeks to be a reliable source of safety components, and aims to be a centre of competence for our customers’ development projects: a place where ideas meet and things happen. The dies are made in-house using a high-speed CNC centre and modern CAD-CAM software. The Engineering Department uses an advanced FEM-3D forging process simulator, which carries out prediction of part defects, prediction of material flow, accurate analysis of final part geometry, the study and optimization of the whole forming process, and the selection of appropriate equipment, extending the life of the dies.

Logistics is a complex function which provides speedy delivery times, conforming products and assistance in despatch for clients all over the world and in every industry. A specialised team prepares production for the dates agreed and approves that production in accordance with the relevant conformity criteria. Clients are kept constantly informed of the state of their orders, and are given adequate assistance to help them organise international shipping. To meet the needs of OEM companies, we can keep special stock either in Feat or abroad, and handle it on the basis of EDI, Kanban or Just-in-Time orders. The logistics service is regarded as being of such importance that it is handled directly by management.